Get an Estimate!

"*" indicates required fields

Confined Space Painting - Safe and Compliant Solutions

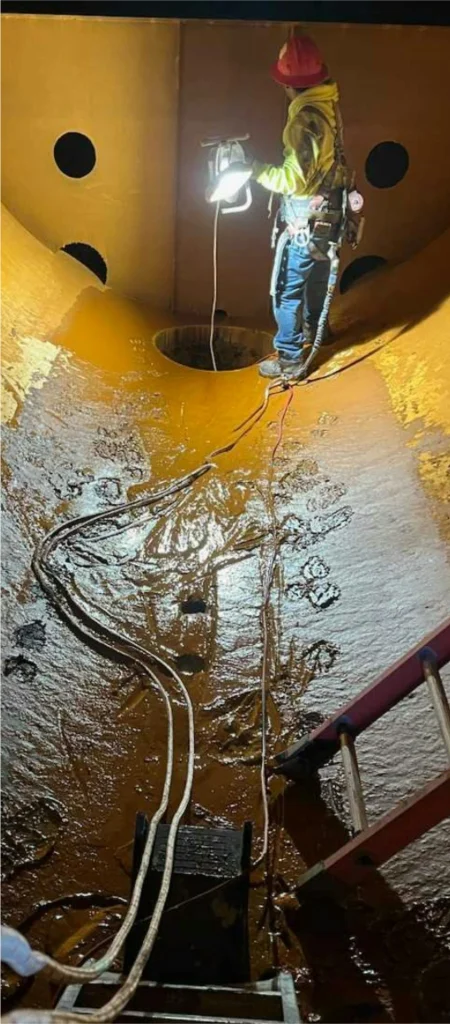

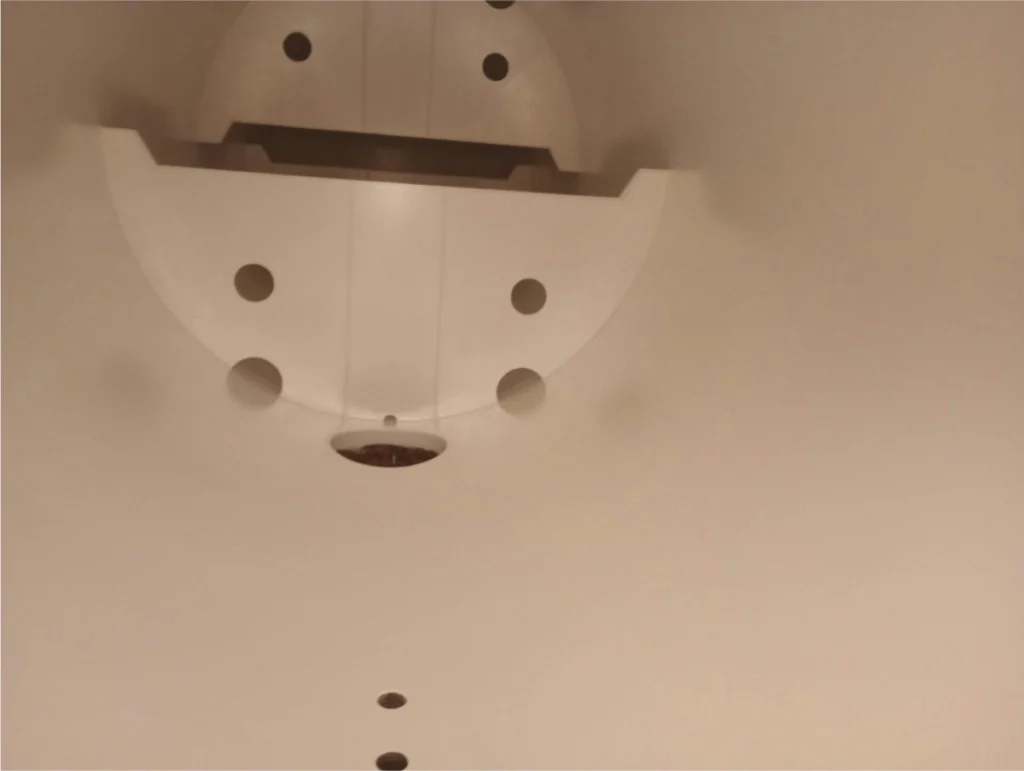

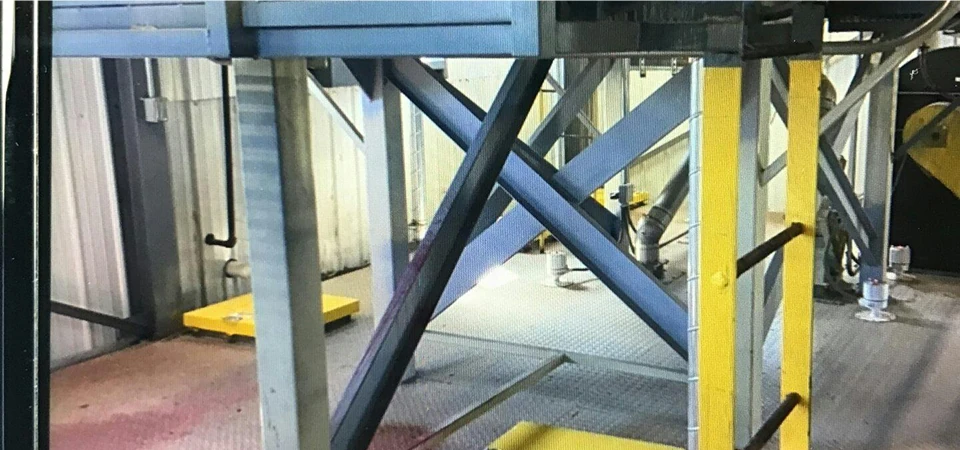

Confined space painting presents a unique set of challenges, from ensuring the safety of the crew to delivering a high-quality finish in environments not designed for easy access. We specialize in navigating these challenges, employing cutting-edge techniques and safety protocols to transform confined spaces such as tanks, silos, and pipelines.

Industrial facilities often have enclosed or confined spaces, examples of which include tanks, storage bins, silos, pipelines, underground vaults, and pits. When confined space surfaces need cleaning, painting, or coating, OSHA compliance is required to avoid hazards and ensure worker safety.

Painters USA has the knowledge and experience you need to understand OSHA confined space characteristics and compliance. We can help you assess and understand permit requirements to find the safest way to complete your project, while staying on time and on budget.

Maximize Efficiency, Minimize Downtime

Confined space projects demand precision and speed to keep your operations running smoothly. Our skilled professionals employ the latest techniques and technologies to deliver high-quality finishes efficiently, reducing downtime and accelerating your return to full operation. Interested in optimizing your project’s timeline without sacrificing quality? Reach out today.

Problems You Have That We Can Solve

Ensure Your Space Meets Safety Standards

Tackling the unique challenges of confined space painting requires expertise that only comes with experience. Our team at Painters USA is committed to ensuring your project complies with all safety and health regulations. Ready to enhance your safety standards with professional, compliant painting solutions? Let’s get started.

Painters USA Confined Space Expertise

Painters USA prioritizes worker safety and may introduce permit-required factors into a project, particularly during the surface preparation phase. We assess potential hazards and consult with clients to ensure compliance and mitigate risks.

With extensive experience in industrial settings, our skilled work crews are trained for safety and proficiency. We offer flexible scheduling and large crews to meet limited downtime needs, equipped with necessary equipment and infrastructure to coordinate with other trades and contractors.

Whether your confined space involves machinery, utilities, or structural elements, Painters USA is your trusted commercial and industrial contractor for the job.

Our safety culture delivers big benefits

Safe workplaces make for a happier, more productive workforce. They reduce legal risks and insurance costs. They assure families that their loved ones will return home from work every day. They give you one less thing to worry about.

Confined space reclassification

Painters USA is always concerned about the health and safety of our workers and yours, which means that sometimes a permit-requiring factor may be introduced into a project. This usually involves the surface preparation phase only.

For example, industrial cleaning methods like abrasive blasting may create a combustible dust hazard during the process, or the best solvent or coating product for the job may be caustic or flammable. We will consult with you in advance if this applies to your project.

We also identify situations that may not require comprehensive monitoring and permits. For example, agriculture clients have facilities with a great deal of permit-required confined space. Yet during off-season, in the absence of running machinery or normal operations, we may be able to rely on Lockout Tagout (LOTO) procedures and other strategies to reduce or eliminate permits and monitoring, yet still meet client and OSHA safety requirements.

However, safety is always our priority. We will not be party to any confined space permit requests if human safety and welfare would be at risk.

See Confined Space Painting Projects We’ve Done

Our happy clients. Both big and small

Achieve Long-lasting Durability.

Durability in confined spaces shouldn’t be overlooked. Our advanced coating solutions are designed to withstand harsh environments while maintaining a professional appearance over time. If you’re looking for a painting service that offers both resilience and durability, you’ve come to the right place.