Industrial Services

- Industrial Services

- Painting

- Airport Hanger Painting

- Automotive Facility Painting

- Brewery Facility Painting

- Ceiling Painting

- Chemical Plant Painting

- Cold Storage Painting

- Conduit and Pipe Painting

- Confined Space Painting

- Ethanol Plant Painting

- Floor Marking and Line Striping

- Industrial Exterior Painting

- Industrial Interior Painting

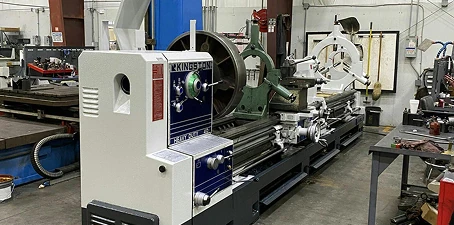

- Machinery Painting

- Metal Building Painting

- OSHA Color Coding

- Silo and Tank Painting

- Structural Steel Painting

- Warehouse and Distribution Painting

- Flooring

- Automotive Manufacturing Facility Flooring

- Concrete Floor Repair and Resurfacing

- Concrete Polishing

- Electrostatic Dissipating ESD Flooring

- Epoxy Flooring

- EV and Battery Facility Flooring

- Floor Marking and Line Painting

- Food and Beverage Processing Flooring

- Industrial Epoxy Floor Coatings

- Industrial Grade Flooring

- Joint Sealing and Caulking

- Non-Slip Flooring

- Thermal Shock Resistant Flooring

- Cleaning

- Painting

- Commercial Services

- Painting

- Ceiling Painting

- Commercial Exterior Painting

- Commercial Interior Painting

- Financial Institution Painting

- Government and Municipal Building Painting

- Healthcare Facility Painting

- High-Rise Painting

- Hospitality and Hotel Painting

- Office Painting

- Parking Garage Painting

- Restaurant Painting

- Tilt-Up and Precast Painting

- Warehouse Floor Markings and Line Striping

- Flooring

- Painting

- Industries Served

- See Our Work

- About Us

- Contact Us

- Industrial

Services- Industrial Services

- Painting

- Airport Hanger Painting

- Automotive Facility Painting

- Brewery Facility Painting

- Ceiling Painting

- Chemical Plant Painting

- Cold Storage Painting

- Conduit and Pipe Painting

- Confined Space Painting

- Ethanol Plant Painting

- Floor Marking and Line Striping

- Industrial Exterior Painting

- Industrial Interior Painting

- Machinery Painting

- Metal Building Painting

- OSHA Color Coding

- Silo and Tank Painting

- Structural Steel Painting

- Warehouse and Distribution Painting

- Flooring

- Automotive Manufacturing Facility Flooring

- Concrete Floor Repair and Resurfacing

- Concrete Polishing

- Electrostatic Dissipating ESD Flooring

- Epoxy Flooring

- EV and Battery Facility Flooring

- Floor Marking and Line Painting

- Food and Beverage Processing Flooring

- Industrial Epoxy Floor Coatings

- Industrial Grade Flooring

- Joint Sealing and Caulking

- Non-Slip Flooring

- Thermal Shock Resistant Flooring

- Cleaning

- Painting

- Industrial Services

- Commercial

Services- Commercial Services

- Painting

- Ceiling Painting

- Commercial Exterior Painting

- Commercial Interior Painting

- Financial Institution Painting

- Government and Municipal Building Painting

- Healthcare Facility Painting

- High-Rise Painting

- Hospitality and Hotel Painting

- Office Painting

- Parking Garage Painting

- Restaurant Painting

- Tilt-Up and Precast Painting

- Warehouse Floor Markings and Line Striping

- Flooring

- Painting

- Commercial Services

- Industries

Served - See Our Work

- About Us

- Contact Us