Get an Estimate!

"*" indicates required fields

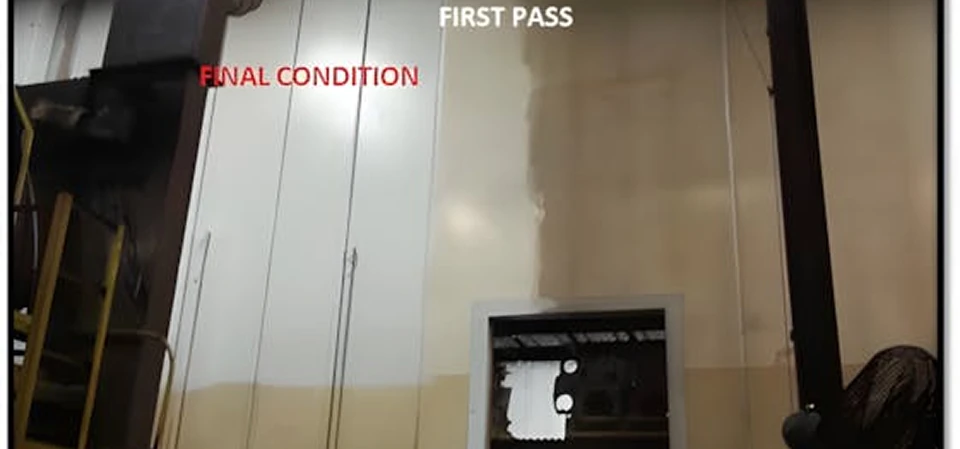

Dry Ice Blasting Services - Clean and Prepare Your Surfaces.

Our dry ice blasting services ensure a thorough, efficient clean with no water, no chemicals, and zero secondary waste. Find out how we can transform cleanliness in your industry, enhancing safety, uptime, and productivity with non-destructive, eco-friendly techniques.

Dry ice blasting utilizes small pellets of dry ice, propelled at high speeds to deliver a powerful yet non-abrasive cleaning method. This technique stands out because it leaves no residue, requires no drying time, and avoids harmful chemicals or abrasive materials. It’s an environmentally responsible solution that enhances equipment longevity, ensures compliance, and maintains pristine environments.

This method is particularly gentle, using dry ice pellets that sublimate upon impact into harmless CO2 gas, thus eliminating the need for specialized ventilation or breathing equipment. The process is fast, safe, and efficient, operating solely on a consistent voltage supply. Any residual dirt and debris can be easily disposed of, minimizing the risk of collateral damage to surrounding areas while effectively removing contaminants like peeling paint or rust.

Ideal for a variety of industrial and commercial cleaning and surface preparation tasks, dry ice blasting is perfect for treating sensitive equipment and surfaces. It can clean delicate areas or remove stubborn contaminants without requiring disassembly, thereby saving time and costs. At Painters USA, we pride ourselves on our exemplary safety record and our ability to leave facilities enhanced with no trace of the cleaning process remaining.

Applications for dry ice blasting include:

- Food and beverage processing tables, conveyors, ovens, packaging and other equipment

- Heat exchangers

- Milling and tooling

- Aircraft and automotive components

- Generators, compressors, engines and compartments

- Pipes, hoses, and fittings

- Solar energy and hydroelectric power structures

- Complex robotics, hydraulics, and electronics

Update your Cleaning Standards Now

Say goodbye to abrasive methods, unnecessary downtime, and environmental concerns. Our experts are on standby to transform your maintenance routine into a seamless, efficient process that aligns with your operational goals. Ready to elevate your facility’s cleanliness and safety? Let’s get started today.

Problems You Have That We Can Solve

Optimize Your Operation’s Uptime

Don’t let extensive cleaning processes hold back your productivity. With dry ice blasting, you get minimal downtime and a rapid return to service, ensuring your operations run smoother and more efficiently. Interested in maximizing your operational uptime? Contact us to see how we can help.

Our happy clients. Both big and small

Get Your Project Done With Minimal Downtime.

We work around the clock to ensure your business continues uninterrupted. From evenings to holidays, we can work around your planned downtime. When it comes to shutdown work, we’re pros.