Get an Estimate!

"*" indicates required fields

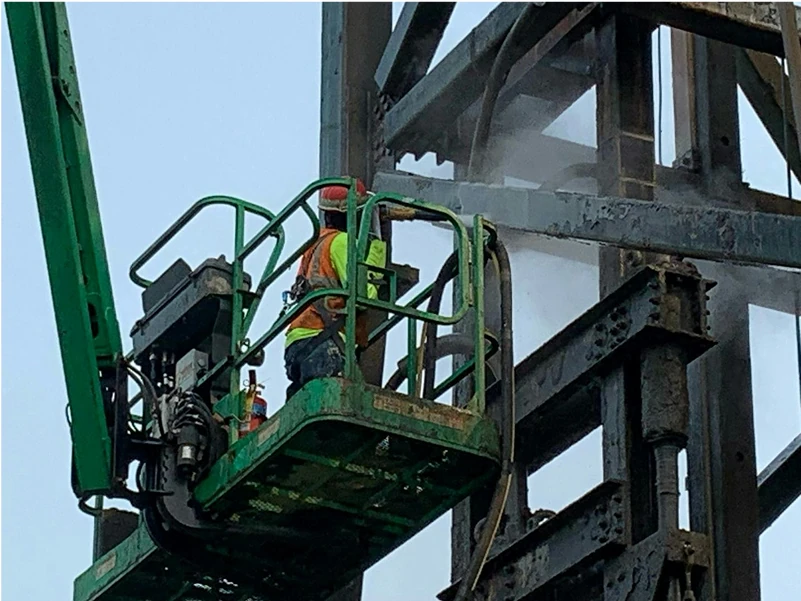

Wet and Vapor Blasting Experts – Cleaning and Surface Prep.

Designed for delicate finishes to heavy-duty industrial cleaning, our services are tailored to meet the specific needs of your project. Discover how our expertise can enhance the durability and appearance of your surfaces, ensuring they are ready for any finishing or coating.

Wet blasting, also known as vapor blasting or slurry blasting, combines the precision of abrasive materials with the softening power of water and delivers a superior clean without the harshness associated with traditional sandblasting methods. This innovative technique not only meticulously cleans surfaces but also prepares them for coatings, ensuring an optimal foundation for any finishing work. Whether you’re dealing with delicate historical restorations or robust industrial machinery, our wet blasting services are engineered to provide a clean, polished finish while preserving the integrity of the underlying material.

At Painters USA, we understand the critical role of surface cleanliness and preparation in the longevity and performance of coatings. Our expert wet blasting services are designed to meet the diverse needs of our clients, from intricate restoration projects to large-scale industrial cleanings. With minimal environmental impact, reduced dust generation, and unparalleled surface finish quality, our solutions are your answer to advanced cleaning and precise surface preparation challenges.

Other benefits of vapor-assisted blasting

- Excellent for surfaces that need to be quickly cleaned and ready for new coating or re-coating.

- Operators can work more precisely and efficiently for enhanced productivity.

- Safer and suitable for confined spaces since health risks are lower.

- More environmentally friendly as it uses less water than wet blasting and less abrasive media than dry blasting.

- Coatings applied after vapor blasting perform better and last longer as the surface is well-cleaned and scored.

- Less damaging to substrates, equipment, and adjacent areas.

- By varying air pressure control, water and water injection control, and blasting media it can be used on nearly any surface.

Achieve Pristine Surfaces

Transform and revitalize your surfaces with precision and care. Our expert team is on standby to guide you through our tailored wet blasting solutions, designed to tackle even the most challenging projects with ease. Ready to improve your standards and bring new life to your surfaces?

Problems You Have That We Can Solve

Painters USA utilizes vapor-assisted blasting, which is suitable for delicate surfaces and diverse industrial environments like airports, bridges, and factories. Adhering to industry standards and regulations, we ensure safety by employing proper blasting materials, dust collectors, and personal protective equipment (PPE). Our expertise extends to various structures, including concrete tilt-ups, machine shops, metal structures, shipyards, silos, and parking garages, ensuring efficient and compliant cleaning solutions.

Preserve Your Investment

Safeguard the integrity and history of your sensitive or historical surfaces with our gentle yet effective wet blasting services. Trust in our expertise to maintain and preserve the beauty of your assets without compromise. Isn’t it time to protect your legacy with precision care?

Our happy clients. Both big and small

Minimize Downtime.

Our expert team ensures swift project execution, allowing you to resume operations promptly. Experience minimal disruption and maximize productivity with our streamlined services. Reach out today to learn how we can help you keep downtime to a minimum and maintain business continuity.