When looking to make the most of the concrete flooring in your commercial or industrial facility, you have many coating options that can be overwhelming. These coatings include epoxy, polyurethane, polyaspartic, MMAs, and urethane cement. You want a floor that is strong and durable, like your business, and worry-free. You want a floor that will withstand daily wear and tear and regular cleaning and maintenance. You want and need to keep your employees safe and meet any applicable industry or government regulations. You want a floor that will last.

When figuring out the right kind of floor for your business needs, there are a few questions to ask yourself.

- Downtime: Normal operations must stop while any coating is applied, so one of your first questions should be, "What is the required turnaround time?" Different coatings have different return-to-service times.

- Temperatures: What is the normal temperature range in the facility? Will there be excessive heat or cold or wide temperature swings? Whether it's from normal operations like a walk-in freezer or due to weather like the heat of summer, extreme temperatures require special consideration.

- Cleaning: Do you do hot water washdowns? Do you scrub your floors with caustic, abrasive chemicals?

- Chemical resistance: Concrete is naturally porous. Without the proper protective coating, solvents, acids, alkalis, and other compounds can soak right in, causing the concrete slab to deteriorate from within.

- Anti-slip: Slips, trips, and falls are a leading cause of injuries and fatalities in the workplace, according to the Bureau of Labor Statistics. Please see OSHA 1910.22 regarding the role of anti-slip flooring in commercial and industrial facilities.

- Traffic: How much foot and machine traffic will there be? What types of weight must your floor sustain? Consider everything, including forklifts, carts, storage racks, equipment, products, and anything else your facilities hold.

- Durability: Facility maintenance budgets and downtimes are limited, yet wear and tear goes on and on as an endless force. Durability pays for itself in extended years of useful, uninterrupted life.

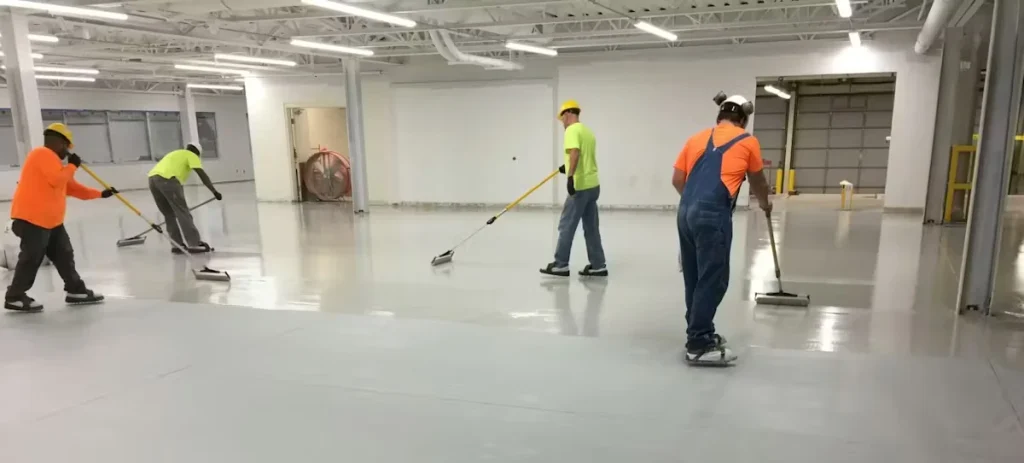

Once you have an understanding of these considerations, and any others that are unique to your setting, turn to the coating experts at Painters USA. We’ll help you understand the difference between epoxy, polyurethane, and urethane—all types of both resin and thermosetting polymers—to figure out which option works best for your operational needs and goals.

The right floor for your needs

Epoxy, polyurethane, and urethane are all great options for durable and long-lasting floors. All three options have different levels of flexibility, chemical resistance, water protection, longevity, and other benefits to fit your unique needs. Following are a few options based on facility type.

Food and beverage processing facilities

- Urethane cement

- Polyurethane

Laboratories

- Polyurethane

- Epoxy

- Vinyl ester

- ESD epoxy

Industrial facilities

- Epoxy mortar

- Epoxy

- Polyurethane

Outdoor areas

- Polyurethane

Epoxy, polyurethane, and urethane are all great options for durable and long-lasting floors. All three options have different levels of flexibility, chemical resistance, water protection, longevity, and other benefits to fit your company’s unique needs.

Painters USA will ensure the perfect fit for your commercial or industrial facilities. Contact us today for an estimate!