Warehouse Floor Markings and Line Striping - 5S Contractor.

Comprehensive warehouse floor markings and line-striping solutions tailored to your needs. Our flooring consultants are dedicated to enhancing safety, efficiency, and compliance in your facility. Learn how we can revolutionize your operations.

Comprehensive warehouse floor markings and line-striping solutions tailored to your needs. Our flooring consultants are dedicated to enhancing safety, efficiency, and compliance in your facility. Learn how we can revolutionize your operations.

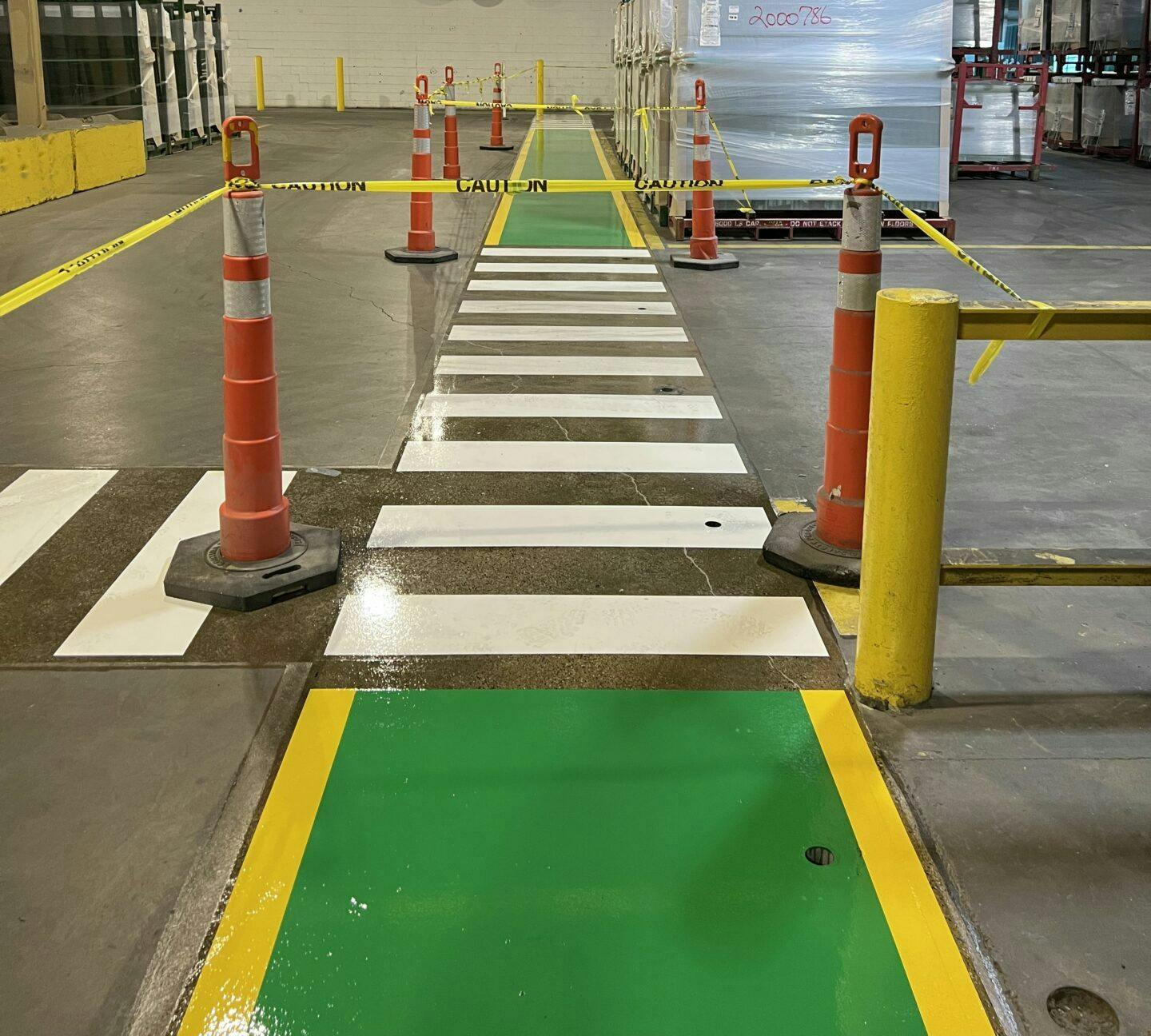

In today’s fast-paced and safety-conscious industrial environment, the clarity and effectiveness of your facility’s floor markings can make a significant difference. Visible floor markings are not just a regulatory compliance requirement; they are essential tools that guide the movement of people and equipment, demarcate hazardous areas, and reinforce the principles of 5S and other quality management systems. At Painters USA, we specialize in providing expertly painted or taped floor marking solutions that enhance the safety, efficiency, and compliance of your workspace.

Our approach is tailored to meet the unique needs of your facility, ensuring that every line, symbol, and indicator serves a specific purpose. Whether it’s delineating walkways, identifying storage locations, or marking equipment boundaries, our floor markings are designed to make your facility a safer place for employees and visitors alike. Let us help you create a workspace that not only meets OSHA standards but also supports your operational goals with clear, durable, and effective floor markings.

See Floor Markings and Line Striping Projects We’ve Done

Take the First Step Toward Safety

Prioritize safety standards and ensure full compliance with industry regulations. Our flooring consultants are poised to tailor a floor marking strategy that enhances operational safety and meets all OSHA requirements. Ready to transform your workspace into a model of efficiency and safety?

Problems You Have That We Can Solve

Forklift accidents are among the leading causes of workplace injuries in industrial settings. Markings clearly delineate lanes and zones to guide operators, enforce rights of way, and minimize collisions.

Protecting workers and visitors is a top priority for industrial / commercial workplace safety. Well-defined walkways, emergency exits, and hazardous areas are just a few ways floor markings can reduce liabilities.

Painted floor markings can be many different colors, depending on needs and purposes. We do everything from universal red and yellow for safety to custom colors for company branding and multi-location consistency.

Marking of permanent aisles and passageways is part of OSHA Standard Number 1910.176 for Handling materials – general. We recommend painted markings for durability and custom colors, but we can also do taping.

Floor markings clearly designate areas for sorting and organizing materials, work-in-progress, and finished goods. They eliminate worker confusion, maximize floor space, and specify functional purpose.

Commercial / industrial facilities can be large, complex places. Well-maintained floor markings create a visual floor map to show the functional purpose of different areas and to guide people throughout the facility.

Happy floor marking / line striping clients

Happy floor marking / line striping clients

Happy floor marking / line striping clients

Why choose Painters USA?

Maintenance is disruptive. You need a team that gets in and out ASAP. That’s why we pride ourselves with our large, well-trained crews that meet your deadlines and minimize downtime – our speciality!

Being on-budget is as important as being on-time, so we prepare accurate estimates and bids for no unwanted surprises.

We aim to meet or exceed quality expectations, backed by warranties and recommending the best materials to balance performance and costs.

For convenience and single-point-accountability, we have the resources and capacity to work across multiple sites in the US, including remote / rural locations.

Our commitment to safety—backed by ISN RAVS Plus® status and an exemplary TRIR rating—reduces workplace hazards and legal / financial risks in your facilities.

Painters USA is fully licensed and insured, and our crews are full-time employees who have undergone thorough background checks.

We are happy to share client references based on your industry or facility challenges and goals for the greatest relevance to your situation.

As a woman-owned business, we can help you diversify and expand your supplier network.

Questions you should be asking

Commonly used colors for floor markings in industrial facilities are yellow, red, white, blue, and green. Yellow indicates pathways and walkways, helping to guide the flow of foot traffic and ensuring a clear and safe route for employees and visitors within the industrial facility. Red is associated with fire safety equipment, emergency exits, or areas with potential danger. White is typically used to delineate boundaries or specific areas. Blue indicates equipment or areas under maintenance, while green often marks safety equipment or first aid stations. Both green and blue are used to color between the border lines of pathways.

Common materials used for floor markings include epoxy paint and thermoplastic or other durable floor marking tapes. Epoxy paint is long-lasting and can provide excellent adhesion to concrete floors. The choice of material should be based on factors like the type of traffic, floor conditions, and expected lifespan of the markings.

The process begins with preparing or profiling the surface for proper adhesion so that the coating will tightly bond to the floor. The designated area is taped and if needed, templates are placed, like stop signs or numbers. The colored paint is applied, generally followed by a clear epoxy or polyaspartic top coating for greater endurance. Finally, all tape and templates are removed and the area is cleared of any other materials for return to full service.

Floor markings should be regularly inspected to ensure their visibility and effectiveness. The frequency of inspections depends on traffic volume and the age and type of markings. A good practice is to inspect floor markings monthly, especially in high-traffic areas or areas exposed to harsh conditions. Any damaged or faded markings should be repaired or repainted to maintain their visibility and functionality.

The lifespan of floor markings depends on various factors, including the type of material used, traffic volume, and the typical operational environment of the facility. Generally speaking, professionally painted lines and markings using performance coatings like epoxy or polyaspartic will have the longest useful lifespan. Tape is a good alternative when frequent floor plan changes are the norm or a long lifespan isn’t a need or priority.

Markings should be wide enough to be easily seen and recognized. For pedestrian walkways or traffic lanes, border lines 2 to 4 inches wide are commonly used. Lanes should provide sufficient clearance for equipment and pedestrians, typically ranging from 3 to 6 feet wide. Aisles dedicated to forklift and truck traffic need to be wider than pedestrian aisles.

In the United States, OSHA (Occupational Safety and Health Administration) provides guidelines for floor marking requirements in different contexts, such as aisle marking, exit routes, or hazardous areas. Additionally, organizations like the American National Standards Institute (ANSI) offer standards for safety colors and floor marking best practices. It’s important to be familiar with the specific regulations and recommendations for your industry and geographical location(s).

OSHA Standard 1910.22 for Walking-Working Surfaces requires permanent aisles and passageways to be appropriately and consistently marked. Aisle and passageway borders need to be at least 2’’ wide so they are clearly visible. OSHA’s general requirement for aisles and passageways is “sufficient safe clearances” where mechanical equipment is used. Emergency exit access points must be a minimum of 28 inches wide.

In some situations, yes. For example, the right use of paint can support HAZCOM (Hazard Communications) requirements, draw attention to electrical equipment and high-voltage areas, provide clear directional guidance for safe and orderly movement of Powered Industrial Trucks (PITs) and identify storage and work areas for hazardous materials.

Line striping and other paint markings promote safety because they are visual cues that are always present to guide and direct employees as they do their work and move around the facility. Functional paint enhances visibility, identifies safe pathways and routes to avoid collisions, and marks potential hazards like high voltage areas or tripping hazards. There is even non-slip / anti-skid epoxy floor paint that reduces the risk of slipping and falling.

Floor markings can play a crucial role in enhancing safety during emergencies or evacuation procedures. They can be used to indicate emergency exits, evacuation routes, assembly points, or areas where emergency equipment is located. By using clear and standardized markings, employees and visitors can quickly and easily identify the appropriate paths to follow in emergency situations. Therefore, it’s important to regularly review emergency floor markings to ensure they align with evacuation plans and comply with relevant safety regulations.

Yes, these kinds of functional painting practices are economical, effective tools to reach and maintain the requirements of many certification programs, as they communicate and define space for standardization, consistency, workflow, worker productivity, and also safety.

Besides safety and compliance purposes, paint can be used to improve efficiency and quality by eliminating errors, enhancing workflow, and improving management of processes, inventory, and other resources. Line striping also helps property owners and facility managers maximize every square foot of costly real estate.

Enhance Your Operational Efficiency

Streamline Your Workflow: Don’t let disorganization hinder your productivity. Our expertly designed floor markings can significantly improve the flow of traffic, reduce waste, and increase efficiency within your facility. Discover how our solutions can be the catalyst for a more organized, productive, and efficient operation. Let’s make every square foot count.

Our happy clients. Both big and small

Maximize Space and Reduce Risk.

Optimize Your Facility Layout: Leverage our expertise to create a visually intuitive environment that maximizes space utilization and minimizes risks. From delineating clear walkways to marking specific storage areas, our solutions are designed to enhance both safety and functionality. Take the step towards a safer, more optimized workspace today.

Optimize Your Facility Layout: Leverage our expertise to create a visually intuitive environment that maximizes space utilization and minimizes risks. From delineating clear walkways to marking specific storage areas, our solutions are designed to enhance both safety and functionality. Take the step towards a safer, more optimized workspace today.